The one with the yeast

- Lin Brendstrup

- 7. jun. 2021

- 3 min læsning

Opdateret: 8. jun. 2021

This Monday the LHAMAS started the day out with a short scrum meeting. Last time we met, the creation of our first brewing process began - and it works! We did however conclude that the stirring mechanism is important, since the production of bubbles/ethanol without stirring stopped after about 24 hours. After the meeting we decided to split up into three groups, since we had some smaller tasks to explore. The main goal for this day was to get an general overview of our product, an idea about which prototypes where next in line to be produced, and how the UI roughly should look.

Team one:

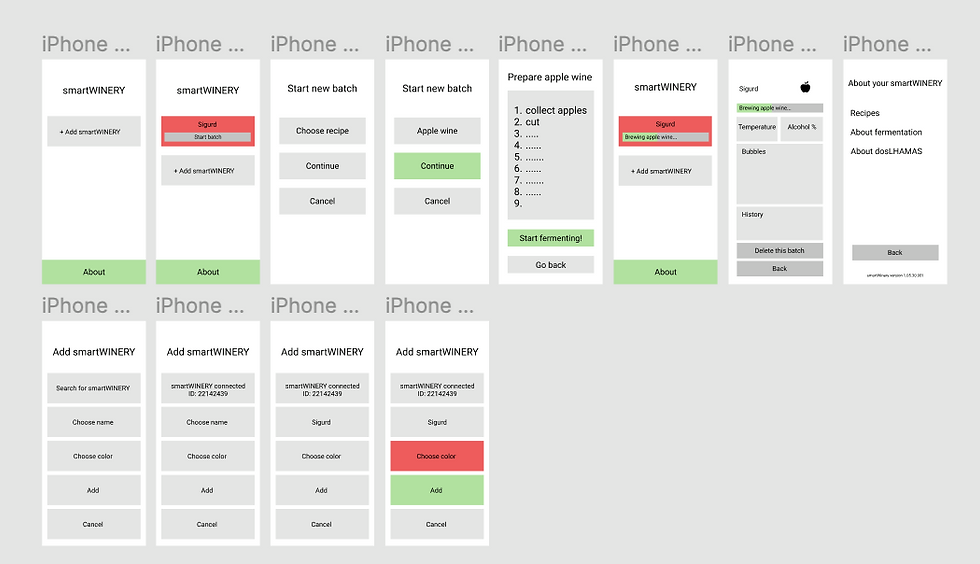

In order to begin planning of the UI needed for the smartWINERY, a wireframing through the program Figma was created. This helped provide an overview on how the user would meet and interact with our product, whilst also helping us begin the development of a flow diagram. To work further with this, we need to decide which parts needs to be connected to both Software and Hardware.

Team two:

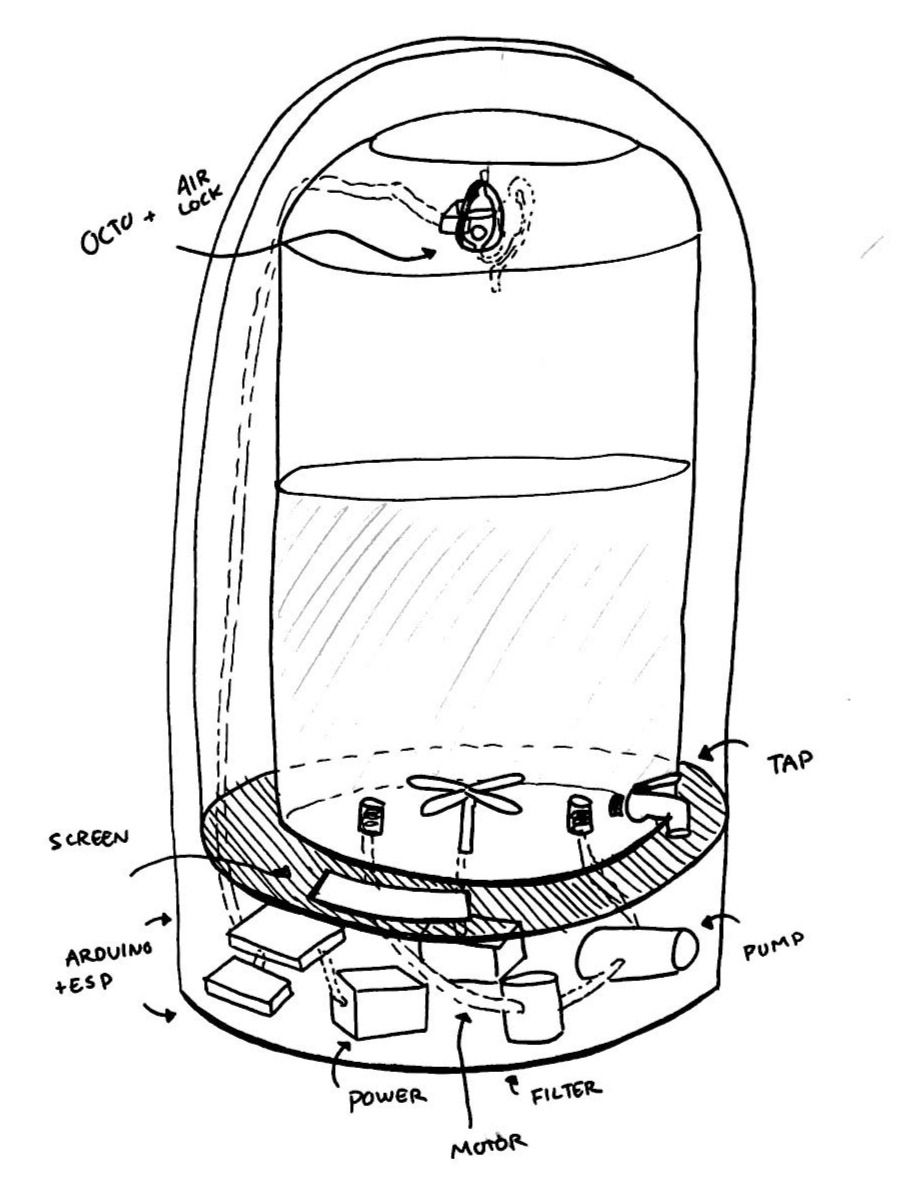

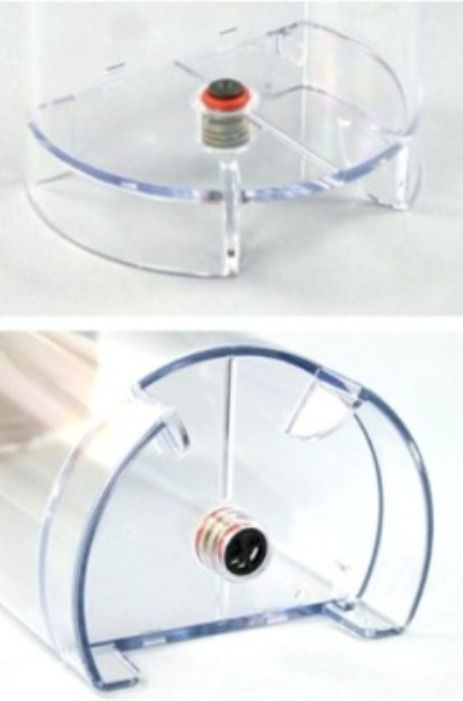

Since we last Friday decided to potentially add a racking mechanism in terms of a filter and a pump, some detailing on the former alpha prototype had to be made. We therefore started an ideation process on the new design. After some heavy thinking, we decided that we wanted both a visual and a functional prototype. This decision is based on the fact that we build our beta prototype around a glass carboy, and therefore are limited by this shape, since we are not able to cut glass.

The functional prototype:

In this first ideation of the functional prototype the airlock is exposed at the top, while the motor for engaging the stirring stick is located in the lid. The wires for the optocoupler and motor are exposed, and the tubes for the filtration system utilizes the hole made for the spout in the carboy.

The visual prototype:

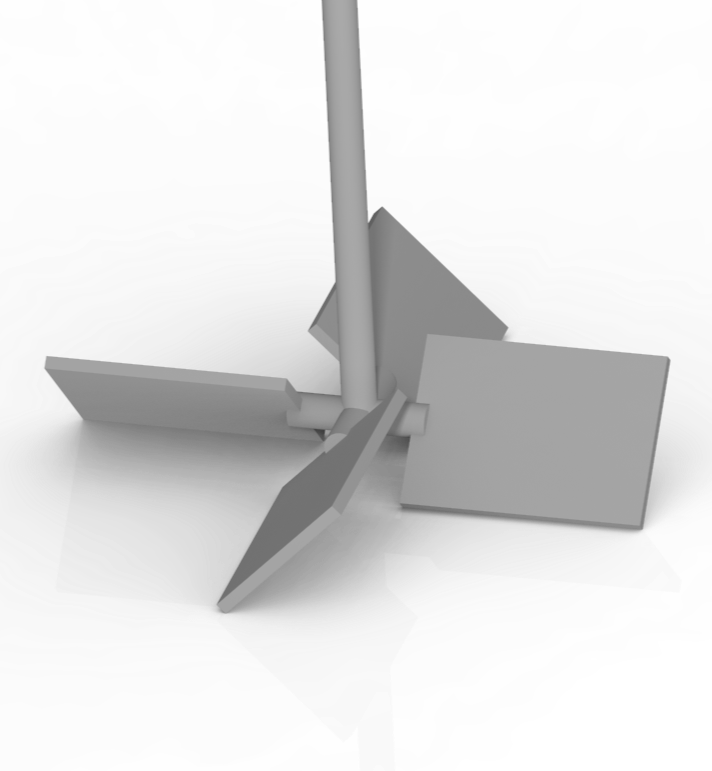

In this prototype the airlock is hidden, but a window allows the user to keep track of the progress. A “wall” on the back, allows a hidden wire to the optocoupler, and the stirring fan is moved to the bottom, like on a blender. Furthermore the filtration system is connected through the bottom, with the same style of connectors as the Nespresso capsule coffee machines. This allows for the carboy to be removed.

Team three:

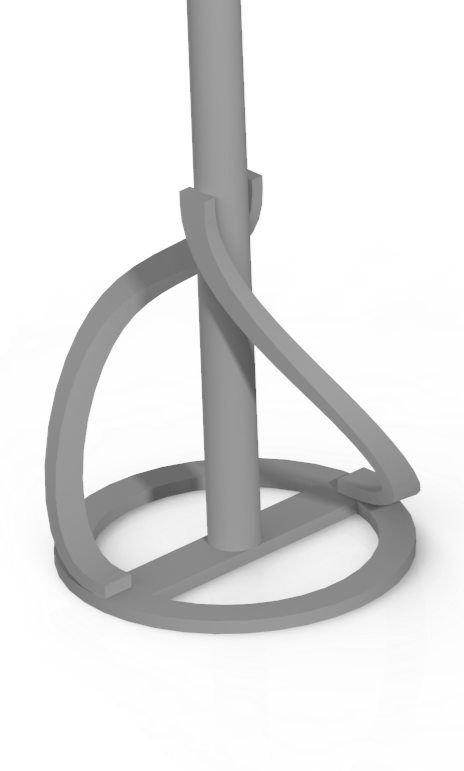

Team three has worked on how to connect the whisk to the motor placed in the lid. This included some research and a purchase of both a peristaltic pump and some tubes. Moreover a bayonet lock and some hose barb reducer fittings needed to be 3D printed. It is important to us that this joint is air proof, since we want to avoid steam from the wine to enter into the lid and disturb the motor. Furthermore some drawings for 3D print of different whisk designs were made, since we want to determine which is the most efficient.

Bonus:

In addition, one of our team members went over to Chr. Hansen, who has been so kind to sponsor us some yeast and other good stuff, made specially for brewing apple wine. We can't wait to use it. We also got some good way tips and tricks on the way, among others that we shouldn't stress the yeast!

Moodboard:

While some of the group members had a bit time to spare, a moodboard of our smartWINERY project was created. This will help us get a get an overall picture of the mood, feeling and expression, we want the smartWINERY to have.

LHAMASTÉ,

dosLHAMAS

Comentarios