Detailing process

- hmladenovski

- 30. apr. 2021

- 4 min læsning

Opdateret: 7. maj 2021

Before you even opened your eyes and made your way out of bed, we at dosLHAMAS had already had our Daily Scrum morning meeting. During this meeting, we spent some time catching up on the idea we decided to go with last week; The Apple Wine Maker. Since we had to pitch our idea in order to get it approved, we refined the concept and named it smartWINERY.

Pain

It is estimated that almost half of apples end up being discarded due to browning (Source: https://www.abc.net.au/radio/melbourne/programs/breakfast/csiro-sending-apple-anti-browning-technology-to-us/9079128). This does not only apply to the apples bought in supermarkets, but also the ones in your own garden. We at dosLHAMAS find this fact problematic and quite upsetting, which is why we wanted to do something about it.

We want to fight fruit waste and make use of the apples (or other fruits), that would otherwise be discarded, by creating a home brewer which allows you to easily brew a sustainably sourced wine in the comfort of your own home.

User Scenario

In order to understand where our smartWINERY would fit into the process of home-brewed apple wine, we wrote the use case out in steps:

Collect very ripe apples (from your own garden or bought from the supermarket)

Make juice from the apples (apples and boiled water)

Pour the substance into the smartWINERY glass gallon

Add ingredients (yeast and sugar)

Add smartWINERY lid to the gallon

Start monitoring the process and keep track on the smartWINERY app on your smartphone

Wait...

Drink your own home-brewed apple wine! Enjoy!

After having cleared things up a bit, we split up into two groups to work on the Function Means Tree and The Prototyping Planners.

Functions means tree

In order to get a better overview of the functions we needed and what means would allow these functions, we created a function means tree. This was a very efficient way of getting to know our product even better in order to develop it further.

As it can be seen in the function means tree, it is definitely in designing the smartWINERY lid, where we need to be smart ;). A lot of different functions is concentrated into the same area, and we therefore needed to gain some more knowledge about the processes in order to make a more qualified proposal for the composition of the lid.

After some research we figured that these were the functions, we needed the smartWINERY to perform for us; Counting bubbles (to inspect the fermentation process), a Stirring mechanism (to occasionally stir the substance), and a Temperature sensor (keep track of the right temperature). We did however discuss the best case scenario where further functions would be added to the smartWINERY, but for a start, this is what we are going with.

Block diagrams

We constructed the following block diagrams to get an overview of the electrical hardware and data flow. The first one you can see is for the electrical hardware:

The second one is for the data flow:

Right now they look quite similar since it is our first draft, and we haven't really looked into the UI yet. This will most likely change, once we get a chance to dive deeper into the smartWINERY.

Prototyping planners

In continuation of the block diagrams we filled out the following prototyping planners. The first one is related to the fermentation process, more precisely counting bubbles as a tool to determine how far the substance is in the fermentation process. We want to make sure that our tests are valid, but at the same time, not spend too much time dwelling over each test, which is why this test in some areas is quite low fidelity. It is however enough for us to eventually develop a viable product.

The second prototyping planner is related to bubbles as well, but now the focus is switched on to the volume of the generated bubbles. It is important for us to have an estimate of the CO2 gas that will be generated, so that we can let the user know how far in the fermentation process the wine is.

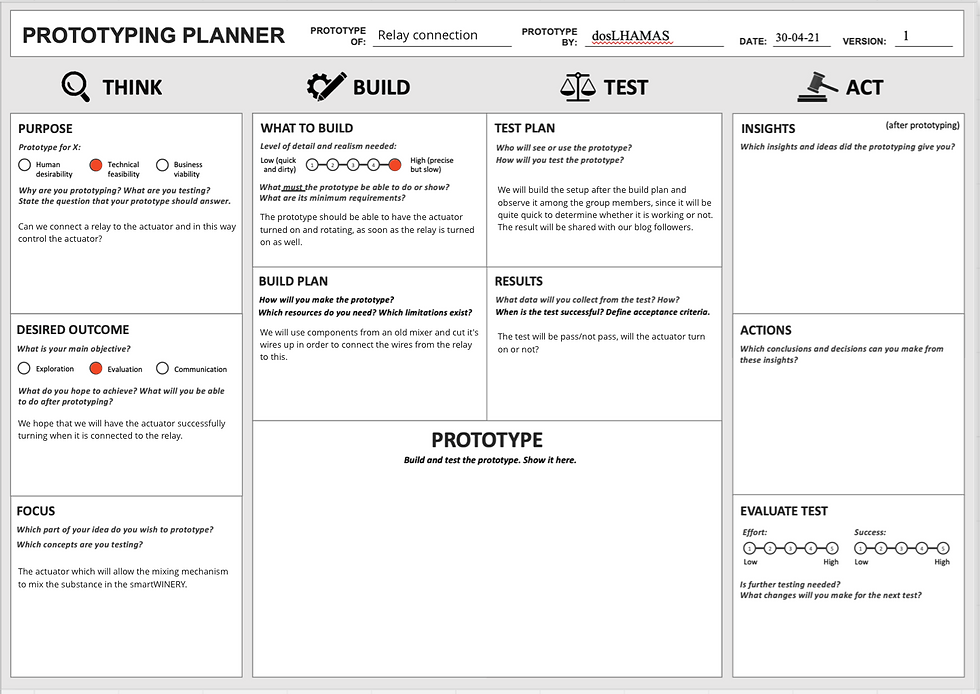

The third prototyping planner is a pass/not pass test, since we are connecting the relay to an actuator (components from an old mixer) in order to see whether the actuator will turn on or not. This is important since we need an actuator to be connected to the smartWINERY lid to make a rotating movement which will occasionally stir the substance.

Photos of the different test setups will follow as we make the tests along the way. The final prototyping planners will be attached to the final blog post as well.

Product requirements document

To utilize our time better, one of today's groups worked on the PRD (product requirement document). This really helped the process along in the detailing phase, as the PRD was not only concerning the technical aspects, but also the end user and which user scenario we had to work around. Click on the link to download and read our Product Requirements Document.

Shopping list

After we gained an overview of the process, we composed a shopping list of the components we needed in order to build the smartWINERY:

Glass gallon

Airlock

ESP8266

IR Optocoupler (counts bubbles going through the airlock)

OLED screen (for key info)

Actuator (to stir the content)

Stirring stick (attached to the actuator)

Yeast

Fruit (in this case apples)

Sugar

We already had the rest of the needed components, so for starters this is our shopping list. Our proposal was accepted, and we ended the day of by ordering the components.

Stay tuned until next week where we will update our progress again. We hope that you are as excited as us about the journey of developing the smartWINERY!

Comments